Make Your Tiles Leakproof

Grouting is a critical process that enhances both the functionality and appearance of your tiled surfaces. By filling the gaps between tiles with high-quality materials such as cement-based or epoxy grouts, we create a durable seal that prevents moisture from seeping in, protecting your tiles, walls, and subfloor from potential damage.

Premium & Professional Tile Grouting Services

Cement Grout

- Cement tiles are an excellent flooring option that adds unique aesthetic appeal to any space.

- Grouting is the process of filling the gaps between tiles to create a smooth, even surface.

- Choose a grout colour that complements the colour of the cement tiles and enhances the overall flooring look.

- Ensure the tiles are clean and dry before grouting for the best adhesion and to prevent discolouration.

- The price ranges from ₹25 to ₹28 per sqft.

Epoxy Grout

- It is highly resistant to water, stains, and chemicals, making it ideal for areas exposed to moisture or spills, such as kitchens, bathrooms, and commercial kitchens.

- Epoxy grout is available in a variety of colors, allowing it to be matched to the tiles or used as a contrasting color for a decorative effect.

- It is easy to clean and maintain, as it does not absorb moisture or dirt like traditional grouts.

- Epoxy grout is highly durable and long-lasting, with a lifespan of up to 20 years or more with proper installation and maintenance.

- The price ranges from ₹30 to ₹35 per sqft.

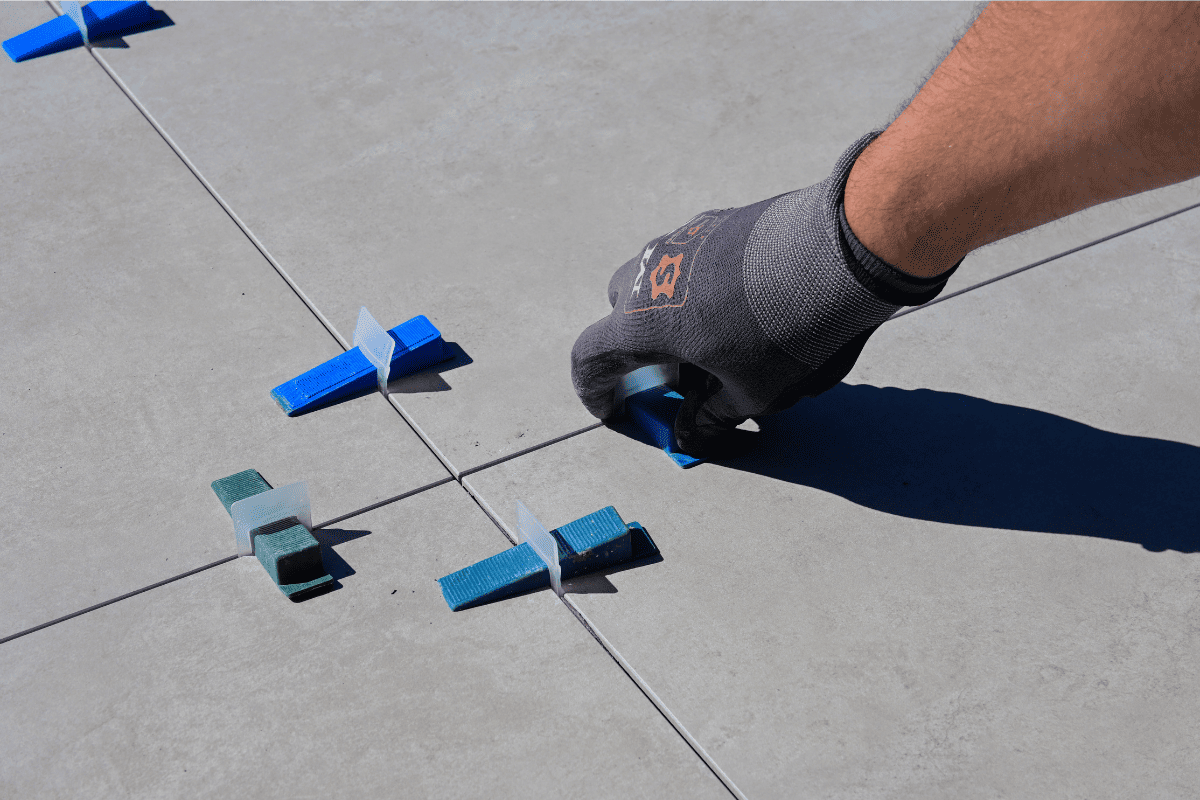

Tile Grouting Application Process

Preparation

Prepare the area where the grout needs to be applied

Cleaning

Clean the joints using the necessary tools

Application

Apply the grout to the dry joints.

Finishing

The grout must be finished and applied while the product is still wet.

Industry Standard Injection Grouting Services

Cement Injection Grout

- The mixture typically consists of cement, water, and sometimes sand or other additives to improve strength and consistency.

- Cement injection grouting can be done manually with a grout float or using a machine designed for the process.

- It can be used for both indoor and outdoor tiling applications, such as in bathrooms, kitchens, swimming pools, and exterior walls and walkways.

- The benefits include improved tile stability, durability, water resistance, and a more uniform and attractive appearance.

- The price ranges from ₹650 to ₹800 per nozzle.

PU Injection Grouting

- The process involves drilling holes into the concrete and injecting the PU material, which expands to fill cracks or voids, sealing the structure and restoring its strength.

- PU injection grouting is widely used in the construction sector for repairing buildings, bridges, tunnels, dams, and other concrete structures.

- It is a quick and cost-effective method for repairing concrete without the need for demolition or reconstruction.

- PU injection grouting can also be used preventively to strengthen concrete structures and prevent future damage.

- The price ranges from ₹1900 to ₹2300 per nozzle.

Injection Grouting Application Process

Drilling

Drill holes into the concrete structure.

Insertion

Insert nozzles or needles into the cracks or voids and hammer them in place.

Packer Installation

Install a packer (one-way valve) connected to the machine.

Injection

Use a pressure machine to inject material into the cracks and voids, filling all hollow areas and allowing the material to dry.

Featured Projects

Project 1, New Delhi

Project 2, Gurugram

Our Process

-

1

Consultation & Planning

-

2

Project Management

-

3

Safety & Compliance

-

4

Final Inspection

Brands Association

Why Trust WeatherGuard for Grouting Services?

Unparalleled Expertise

We have highly skilled teams. Our technicians, supervisors and support staff are trained, certified and equipped to handle complex tools.

Customer Centric Approach

With 24/7 availability and transparent communication at every stage, we deliver a seamless and trustworthy experience.

Longterm Solutions

By using premium materials, advanced techniques, and proven methods, we create durable and reliable solutions.

Quality and Relaibility

We ensure a hassle-free experience with 30+ pre and post quality checks, meticulous attention to detail, and a commitment to on-time project completion.

Safety & Compliance

Our team adheres to strict safety protocols, ensuring a safe working environment and complies with all relavant regulations and industry standards.

20+ Inspection Points

With 20+ detailed inspection points, we meticulously evaluate every aspect of the project to ensure it meets the highest standards.

Innovative Solutions

We leverage the latest technologies to deliver cutting-edge solutions while offering customized, budget-friendly services.

Competitive Pricing

We deliver premium services that combine exceptional quality, reliability, and innovation—all at the best pricing in the market.

Regular Technical Visits

Our team conducts periodic inspections and evaluations to monitor performance, address potential issues early, and ensure ongoing satisfaction.

Have Questions?We’re Here to Help!

Explore our FAQs to find answers to common queries about our grouting services, processes, and warranties.

When should I grout my tiles?

Can I grout over existing grout?

How do I clean grout?

What are the benefits of injection grouting?

- Waterproofing: Helps seal cracks and prevent water leaks in foundations, basements, and tunnels.

- Structural repair: Reinforces and strengthens weakened concrete or masonry.

- Cost-effective: Reduces the need for major structural repairs or replacements.

- Minimal disruption: Can be done without major demolition or disruption to the surrounding area.

- Durability: Provides long-lasting protection and reinforcement.

Can injection grouting be done on wet surfaces?

How do you determine which grout material to use?

The choice of grout material depends on:

- The type of crack (structural or non-structural).

- The environment (wet or dry, exposure to chemicals or moisture).

- The desired flexibility or strength (e.g., epoxy for strength, polyurethane for flexibility and water resistance).

- The size of the void or crack.

Projects Delivered

Businesses Love us

-

John Doe ManagerLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Read more

-

John Doe ManagerLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Read more

-

John Doe ManagerLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Read more

-

John Doe ManagerLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Read more

-

John Doe ManagerLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Read more

-

John Doe ManagerLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Read more

Consult Your Colour Selection With Us

Businesses Love Us

-

Ravi Taneja New DelhiI hired Weather Guard for a contractual project, and they exceeded my expectations. Their professionalism, attention to detail, and timely execution made the entire process seamless. Highly recommended!

-

Rajiv Aggarwal GurugramWeather Guard delivered exceptional quality in our construction project. Their team was professional, efficient, and committed to excellence. The work was completed on time, and I’m extremely satisfied with the results.

-

Sumanth Anto BengaluruA fantastic experience with Weather Guard! From planning to execution, their team maintained high standards of workmanship and communication. Would definitely work with them again.

-

Yasir Farook ChennaiReliable, professional, and highly skilled—Weather Guard did a phenomenal job on our project. The work was completed as per the contract, and the quality speaks for itself. Highly satisfied!

-

Vivek Hegde MumbaiI’m very impressed with the dedication and expertise of Weather Guard. They handled our construction project with utmost professionalism, meeting deadlines and maintaining top-notch quality. Great team!

-

Antariksh Sharma Noida

Excellent service and outstanding craftsmanship! Weather Guard took care of every detail and delivered beyond expectations. Their work ethic and professionalism are commendable.

-

Rishab Nair New DelhiWeatherGuard exceeded my expectations with their professionalism and expertise. The team was efficient, detail-oriented, and completed the project on time. Highly recommended!

-

Anjali Thakur FaridabadI hired WeatherGuard for a construction project, and they delivered outstanding results. Their team was knowledgeable, communicative, and committed to quality. A great experience!

-

Vansh Arora New DelhiWeatherGuard provided excellent service from start to finish. Their attention to detail and commitment to quality made the entire process smooth and hassle-free. Would definitely hire them again!

-

Gaurav Juneja Karnal

WeatherGuard handled my project with precision and care. Their team was well-organized, completed the work on time, and ensured everything was up to the highest standards. Fantastic job!

-

Balbir Randhawa GurugramFrom consultation to execution, WeatherGuard was professional, responsive, and delivered high-quality work. Their expertise and dedication to customer satisfaction are commendable.